Select a Location

It’s flooring—and then some. Made for More.

THE HEALTHIEST PLASTIC

IS THE ONE YOU DON'T USE

We’ve cut our use of virgin plastic significantly. Thanks to a mix of design and material innovations. And the introduction of non-vinyl options like our CQuest™Bio backing.

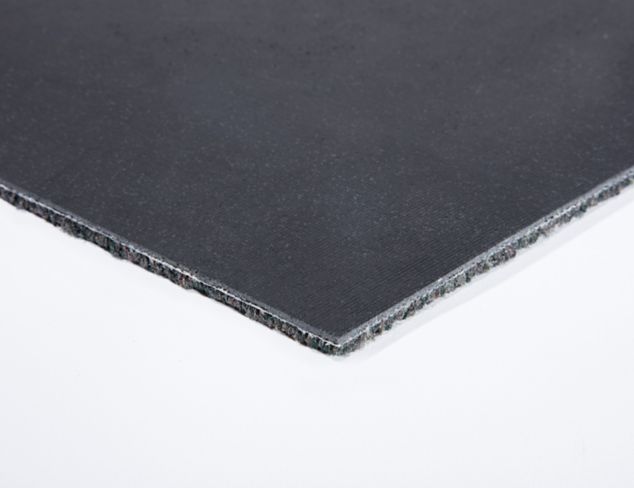

RECYCLABLE

FLOORING

Today, most flooring ends up in a landfill or an incinerator. But Interface offers an alternative. A true closed-loop system for vinyl-backed carpet tile. Made possible by our ReEntry™ collection program.

Forward-thinking ideas. Innovative solutions. This is how we safely make new flooring from old.

ALL PVC IS NOT CREATED EQUAL

PVC use continues to grow. And this is despite efforts like Red Lists.

Specifiers need a way to ask for better PVC. Enter the Green Star Best Practice Guidelines. A standard that eliminates traditional concerns about the manufacture of PVC, harmful additives, and end of life.

Some products claim to be “PVC Free.” But that alone doesn’t make them healthy or sustainable. We evaluate all materials (including PVC plastic). And we consider their contributions to green chemistry, circularity, and carbon reduction.

WHY GREEN STAR?

No material is without its trade-offs. We use Green Star Best Practice Guidelines globally for PVC. But that doesn’t mean PVC is 100% sustainable.

Why Green Star? It is the only independent, comprehensive standard for best practice PVC that exists today. And though it’s specific to Australia, we apply the guidelines globally.

Eventually, we want to use only recycled or bio-based inputs. But that’s a long-term goal.

We’ll continue to responsibly use PVC for now. But not forever.